When a London hospital needed to install new mammogram equipment in a listed building, there were several issues to address.

When it comes to upgrading healthcare facilities, balancing modern medical needs with the preservation of historic buildings is no easy task.

The solution? Prefabrication. This innovative construction method allowed us to deliver high-quality, patient-centric Mammogram Pods that met the stringent regulatory and historical requirements without compromising on speed of delivery or quality.

The Unique Challenges

London is synonymous with medical excellence but its historic nature posed specific challenges for our team. The rooms required state-of-the-art medical equipment that complied with strict healthcare regulations, including radiation shielding for mammography. However, the building’s listed status meant we couldn’t alter or connect to the walls, floors or ceilings – a major obstacle in traditional construction.

Mammograms require intimate, private spaces that help patients feel at ease during a procedure that can often be uncomfortable. The large, high-ceilinged rooms were far from suitable for this purpose. We needed to create smaller, clinical environments inside these larger spaces which prioritise quality, safety and infection control.

The project was further complicated by the need to maintain the building’s integrity and comply with stringent regulatory requirements for listed buildings. These conditions called for an innovative approach – one that traditional construction simply couldn’t meet without significant disruptions and costs.

The Prefabrication Solution

Faced with these challenges, prefabrication emerged as the most viable solution. Unlike traditional construction, which would have involved invasive work on-site, prefabrication allowed us to build high-quality, customisable mammogram pods off-site before transporting and installing them with minimal disruption.

At Architectural Wallsz, our prefabricated units are manufactured in controlled environments to ensure each component meets the exact specifications and standards required by healthcare facilities. For this project, we designed freestanding mammogram pods that didn’t need to connect to the existing structure, which solved the issue of the listed building’s restrictions.

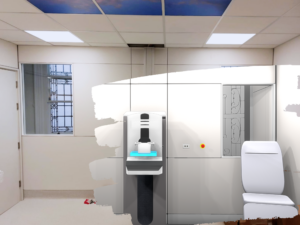

These pods were fitted with all the necessary radiation shielding, infection control features and medical equipment integration. Importantly, the pods were designed to be smaller, more intimate spaces within the larger rooms to provide a comfortable, private environment for patients undergoing mammograms.

Design Collaboration and Virtual Reality

One of the key factors in the success of this project was the close collaboration between Architectural Wallsz and the client. From the outset, we worked closely with the client’s project team to ensure every detail was accounted for.

To help visualise the final product, we provided 3D flythroughs and even gave the team the chance to walk through the design using virtual reality (VR). This allowed them to see exactly how the mammogram rooms would look and feel and allowed them to make further suggestions before the construction phase began. This design transparency ensured there were no surprises when the pods arrived on-site and it also helped eliminate the risk of costly variations or delays once installation began.

Efficient, On-Time Installation

Once the design was finalised and approved, the prefabricated pods were built off-site and delivered for installation. Thanks to the precision of the prefabrication process, we were able to install the mammogram pods in just three weeks – a fraction of the time that traditional construction would have required.

This efficient installation was a huge advantage for our client. As the prefabricated pods were manufactured to exact specifications, there was no need for on-site adjustments or reworks. The installation process was smooth, with minimal disruption to the daily operations of the healthcare facility and no hidden costs.

The freestanding design of the pods meant the integrity of the listed building remained intact, which was crucial for meeting the building’s regulatory requirements.

Long-Term Benefits of Prefabrication

The long-term benefits of the prefabricated mammogram pods extend far beyond their quick installation. The new pods provide a private, comfortable space that enhances patient experience.

The flexibility of prefabricated systems means the pods can be easily adapted or reconfigured in the future as needs change. This flexibility makes prefabrication a future-proof solution and allows healthcare facilities to evolve and expand without the need for major renovations or extended downtimes.

The Future of Healthcare Construction

The success of this project highlights the growing importance of prefabrication in healthcare construction.

By using prefabricated solutions, healthcare providers can meet their immediate needs while also ensuring their facilities are adaptable for the future. This project exemplifies how prefabrication can solve complex construction challenges and deliver high-quality, patient-centric solutions that are built to last.

At Architectural Wallsz, we’re proud to be at the forefront of this construction revolution and offer flexible, sustainable and efficient solutions for healthcare facilities across the UK.

Prefabrication isn’t just the future of construction, it’s the present and we’re leading the way. Contact us today to find out more.

Sorry, the comment form is closed at this time.